- Related articles

- All Cisco X2-10GB-ER's information (List price, Specs, Datasheet PDF, Compatibility matrix

- Optical Transceivers for Cisco N6K-C6001-64P Switch

- Optical Transceivers for Cisco SG350XG-24T-K9-UK Switch

- What is motherboard network card?

- What is CFP transceiver?

- How to Identify Fiber Optic Cable?

- What is a single mode fiber?

- Optical Transceivers for Cisco WS-C3650-48FQ-L Switch

- Optical Transceivers for Cisco WS-C3750E-24TD-SD Switch

- Optical Transceivers for Cisco SG250-26P-K9-UK Switch

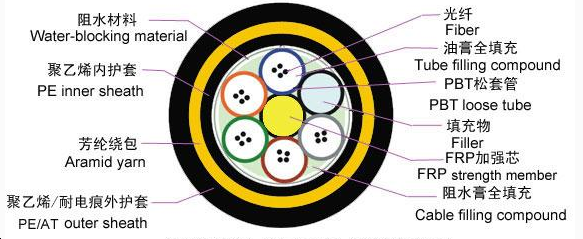

Structurally, fiber optic cables are more complex than what we just see, a fiber optic cable involves 8 kinds of materials at least . Furthermore, different fiber optic cables include different materials and designs which make them a little bit costly. So there are many inferior cables in the market supplied at low price, which gives people difficulties to get high-quality products. But it is still able to identify by the appearance and performance, as bad materials would cause evidence on products.

Below are listing some useful experiences from the structure of fiber optic cable to give you ideas for identification.

Outer skin

For outdoor and indoor fiber optic cables, we can identify from appearance’s features by below:

Appearance of high quality | Appearance of poor quality | |

Outdoor optical cable | smooth, bright, pliable | poor finish, sticky |

Indoor optical cable | flat, no bubbles, bright, even | rough, uneven |

| Appearance |

High-quality cable | gray, stainless, strong |

Poor quality cable | white, easily bend and rusty |

Appearance | Material | |

High-quality cable | rust-proof | steel |

Poor quality cable | without rust-proof | iron |

| Appearance | Material |

High-quality cable | Strong, non-deformation, anti-aging | PBT |

Poor quality cable | thin, easily deformed | PVC |

Performance | Filling method | |

High-quality cable | highly anti-water | Fully filling |

Poor quality cable | easily damaged by water | Incompletely filling |

Performance | Material | |

High-quality cable | strong and tough | enough Kevlar used |

Poor quality cable | thin, easily broke | less Kevlar used |

Performance | Material | |

High-quality cable | strongly water-absorbing | Water-absorbent resin |

Poor quality cable | non water-absorbing | nonwovens or paper |