- Related articles

- All Cisco ONS-SI-155-L1's information (List price, Specs, Datasheet PDF, Compatibility mat

- Optical Transceivers for Cisco C3850-NM-8-10G= Switch

- All Cisco SFP-10G-LR-X's information (List price, Specs, Datasheet PDF, Compatibility matr

- What is wave division multiplexing?

- Optical Transceivers for Cisco DS-X9232-256K9= Switch

- What is Opto Electronics?

- Optical Transceivers for Cisco SG550XG-24T-K9-UK Switch

- Optical Transceivers for Cisco SG300-10SFP-K9-EU Switch

- All Cisco GLC-BX40-U-I's information (List price, Specs, Datasheet PDF, Compatibility matr

- What Is GJFJV Fiber Optic Cable?

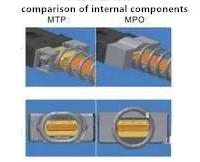

With the rapid development of data center, cloud counting, cloud reservation and other applications have been gradually permeated into different industries. The bandwidth requirement of internet telecommunication also increases dramatically and the bandwidth with high speed and large capacity needs larger space and higher cost, in which there is a long time contradiction. MTP/MPO fiber wiring standard has become the present best solution for wide bandwidth of high density. Nowadays there are two fiber connected system in the market, MTP and MPO. They are very similar to each other and they can be compatible to some degree, but what’s the difference between them?

What is MPO connector?

MPO is the English abbreviation of “multi-fiber pull off”.The number of this connection head’s core insert is more than one, inserted through the mechanical way.

Now, there are various MPO designs of manufacturers in the market. Connector products of different types have a big difference in terms of their functions and costs. Some products’ features make their functions more unique. Some MPO connectors can match with many products of different brands while others cannot. This match depends on the design similarity of those connectors to the standard products. The complete definition of MPO connector should be seen by reference to the complement of IEC-61754-7 and EIA/TIA-604-5 (aka FOCIS 5).

What is MT core insert?

MT refers to the mechanical butt joint transmission with multi-cores (generally 12 cores). The connector function depends on fiber’s registration precision and stability of registration precision after connection. Finally, this registration precision depends on fiber’s eccentricity ratio, distance, and its matching precision. If the deviation caused by the guide pin and molding technology is reduced, any MPO connector’s function will be improved.

What is MTP fiber connector?

MTP fiber connector is a connector with multiple innovative design and high performance. Compared to the general MPO connector, MTP fiber connector has intensified its optical and mechanical function. MTP connector perfectly reaches the professional standard of all MPO connector, including EIA/TIA-604-5 FOCIS 5 and IEC-61754-7.

MPO connector is the matching connector that reaches the industrial standard, which means that replacing MPO connector with MTP connector for the better function is feasible. Most performance following that of old versions of MPO connector is very limited and cannot provide the same high performance of MTP.

Why is MTP connector described as high-performance MPO connector?

Compared to MPO connector head, the performance and availability of MTP connector with special design have been improved. Characteristics of MTP’s design are unique and protected by patent. The main features are as follows:

1. MTP fiber connector’s outer frame and embedded spare parts are convenient for removing.

MTP core insert’s design ensures its performance from the loss when reworked and reground in the process of producing. Polarities of Yin and Yang can even flexibly change on the scene and pass the interference test after assembling.

2. The floating core insert of MTP fiber connector can improve the transmission performance of mechanical connection, allowing the matching core inserts of two connectors to keep fine physical contact under the influence of an external force.

3. The stainless steel texture is used for MTP fiber connector’s elliptical pin, which can not only improve the connection precision but also reduce the abrasion of guide hole, making MTP fiber connector keep high-performance transmission longer.

4. A metal needle clamp is inside MTP fiber connector to immobilize the throw-out collar. Specific features are as follows:

1) Preventing pin from losing;

2) Centralizing the pressure produced by spring;

3) Preventing spring from touching friction fiber in the process of mechanical expansion and contraction which causes the damage to the fiber;

5. The increase of 12 cores in the highest limit of MTP fiber connector design and the band gap of multi-core band applications prevent the fiber from damage.

6. At least four matching separations for MTP fiber connector can adapt to different fiber cable types with more practicability, including:

1) Loose joint-structured round fiber cable;

2) Ellipse-coating band fiber cable;

3) Band bare fiber;

4) Very short tail-cuff connector separations: suitable for a narrow space and reducing 45% volumes.