- Related articles

- Why Do We Need Optical Fiber to Get to the “Cloud”?

- What Is Wireless Network Interface Card?

- All Cisco DS-SFP-FC8G-SW’s Information ( Overview, Features, Datasheet PDF, Price, Specifi

- What is a DWDM transceiver?

- All Cisco QSFP-40G-CSR4's information (List price, Specs, Datasheet PDF, Compatibility mat

- Optical Transceivers for Cisco DS-X9232-256K9= Switch

- The Things You Need to Know about 10GBASE-SW Ethernet Standards

- What is motherboard network card?

- Optical Transceivers for Cisco WS-C3750V2-48TS-E Switch

- Optical Transceivers for Cisco WS-C3750G-12S-S Switch

Pipeline installation is one of the common ways of laying fiber optic cables. Comparing with direct-laying, pipeline laying can provide extra protection for fiber optic cables. However, as we all know that the transmission of optical cables is quite easily affected by tension, bending radius and lateral pressure. Therefore, there should be given extra attention when laying fiber optic cables in pipe.

Before laying, it is necessary to first understand the pipeline. According to the material, the pipeline can be divided into concrete pipe, plastic pipe, steel pipe, cast iron pipe, asbestos cement pipe and others. Among them, plastic pipe is the most common pipe, which has the advantages of light weight, smooth wall, simple connection, good water-tightness, good corrosion resistance, good insulating property and convenient transportation. Below is a common plastic tube - seven holes Plum.

Pipe laying

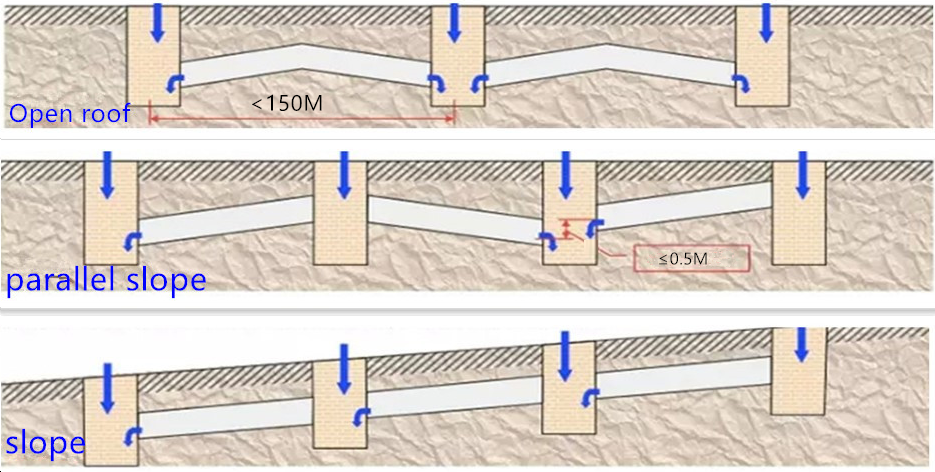

As mentioned above, pipe is normally buried under the ground. In order to prevent the pipe being damage, when laying cables in pipe, it’s not enough to only focus on the rules about street protection, also the gradient of pipe itself should be given attention as it’s related with the total cost of laying. Generally pipe can be laid into 3 grades: Open roof, word slope and slope as following shown:

Fiber optic cable laying

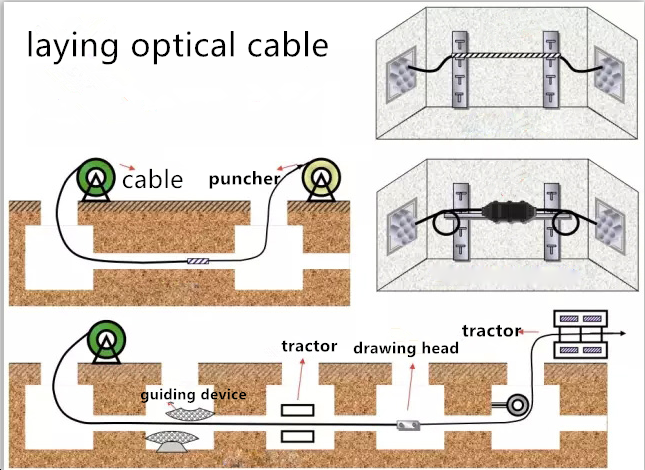

There are two ways of laying fiber optic cables in pipe: manual traction and mechanical traction. Normally, manual traction is applied for short distance laying, mechanical traction is applied for long distance laying. What should be noted is a traction should not exceed the allowable tension of the cable. The following respectively shows the operation of manual traction and mechanical traction:

Conclusion

It usually requires more efforts and focus when laying pipe fiber optic cables than others due to the complexity of pipe and rules of surroundings and also safety. Pipe fiber optic cables are getting widespread in more and more areas with the development of society as a important part of fiber optic communication.