- Related articles

- What is an Ethernet card?

- Buy Cisco GLC-SX-MM SFP For Fiber Optic Networks

- Naming of Fiber Optic Cable

- All Cisco DWDM-XENPAK-58.98's information (List price, Specs, Datasheet PDF, Compatibility

- Optical Transceivers for Cisco N3K-C3548P-10G Switch

- Optical Transceivers for Cisco SG102-24-UK Switch

- Optical Transceivers for Cisco SF350-48-K9-UK Switch

- Optical Transceivers for Cisco N3K-C3172PQ-XL Switch

- Optical Transceivers for Cisco SG500X-48P-K9-G5 Switch

- Optical Transceivers for Cisco N5K-C5010P-B-S Switch

What Does a Fiber Optic Cable Look Like?

Fiber optic cables, from the outside at least, don’t look drastically different from many other kinds of cabling, since their outermost layer tends to be a colored plastic or silicon tubing. It’s common for them to be white, grey, or black in color, but there are more colorful options available if that’s useful. It can sometimes denote a specific feature, too. For example, fiber optic patch cables can have an orange color to denote that its a multimode optical fiber cable, or a yellow jacket to make it clear that it’s a single mode optical fiber cable.

The end of the cable will look different depending on the type of task the fiber optic cable is used for. A TOSLINK optical fiber cableused for audio transmission has a small plastic tip that will show the visible light being transmitted by the cable when plugged in at one end, while a fiber optical patch cable may be fitted with a connector called an LC connector at each end. It can still be visible in some cases, however, and in the case of a laser transmitted light, should not be viewed directly as it can cause severe eye damage.

Types of fiber optic cables

Due to the extensive application and complicated structure of fiber optic cables, we can sort fiber optic cable into different types considering from different views. If in a detailed way, the types of fiber optic cable could be as following:

| View | Type |

| Transmission distance and application |

Fiber optic cable for user Local fiber optic cable Long distance fiber optic cable Submarine fiber optic cable |

| Types of optic fiber |

Single mode fiber optic cable Multiple mode fiber optic cable |

| Amount of optic fibers |

Single core fiber optic cabl Multiple core fiber optic cable |

| Collocation methods of FRP |

Center reinforcing member cable Dispersion reinforcing member cable Sheath reinforcing member cable Integrated outer covering cable |

| Transmission conductor and medium status |

Non-metal cable Ordinary cable Integrated cable |

| Paving pattern |

Pipeline fiber optic cable Direct-buried optical cable Overhead cable Underwater fiber optic cable Field cable |

| Structure |

Flat structure cable Layer twisted cable Skeleton cable Armored cable High-density user cable |

| Maintenance methods |

Oil-filled cable Inflatable cable |

| Looseness status of optic fiber in cover layer |

Loose-packet optical fiber cable Tight package fiber cable |

While in a general way, fiber optic cable is also sorted into several main types, such as single mode cable and multi-mode cable, indoor optical cable and outdoor optical cable, loose-tube cable and tight-buffered cable.

Definition of main types of fiber optic cable

Single mode optical cable is a cable that is only able to transmit single beam of light at once, which makes it suitable for long distance transmission, as a result of there are no multiple light beams to bring interference.

Single Mode Fibers – OS1 and OS2

Single Mode fibers are identified by the designation OS or Optical Single-mode Fiber. Single Mode cable has a much smaller core (8-9um) than multimode cable and uses a single path (mode) to carry the light. The main difference between single mode OS1 and OS2 is cable construction rather than optical specifications. OS1 type cable uses a tight buffered construction while OS2 is a loose tube or blown cable construction.

OS1 Single Mode Tight Buffered Cable

Tight Buffered 12 Core

Each fiber has its own protective two-layer coating (color-coded for identification). One layer is plastic and the other is waterproof acrylate. The tight buffer allows for a smaller, lighter weight cable that is more flexible and crush resistant than Loose Tube. Installation is easier as there is no gel to clean up and no fan out kit required for connector termination.

Application:(Indoor Use) – moderate distance telco local loops, LANs and point-to-point links in cities, buildings, factories, office parks or campuses. OS1 can support speeds up to 10G and distances up to about 10km (6 miles).

OS2 Single Mode Loose Tube Cable

Loose Tube 12 Core

All fibers are essentially bare other than their outer coating. Each fiber has a colored coating for identification. Other than this coating the fiber “floats” within a rugged, abrasion resistant, oversized tube usually filled with optical gel which protects the fibers from moisture. Connector termination requires a fan out kit.

Application:(Outdoor Use) high fiber count, long distance telco backbone and backhaul lines, direct bury applications along streets and railroads. OS2 can support speeds up to 100G and distances up to 200km (124 miles).

Single Mode Fiber Summary

Single Mode jacket color is typically yellow for jumpers but you may see a variety of colors depending on the application and the outer jacket type.

Single mode fiber is the standard choice for high data rates or long distance spans and can carry signals at much higher speeds than multimode fibers with less signal attenuation and external interference. It offers many advantages over multimode fiber and is an effective way to future proof your network cabling infrastructure.

Multi-mode optical cable has a little bit bigger diameter in optic fiber core than single mode cable, it could transmit multiple different light beams at a time, and each light is sent at a different angle so beams would not interact with each other, the multiple paths of light can cause signal distortion and result in an unclear and incomplete data transmission at the receiving end, which makes them only available for short distance transmission.

Loose-Tube Cable, is specifically designed for harsh outdoor environments. It protects fiber core, cladding and coating by enclosing everything within semi-rigid protective sleeves of tubes. In loose-tube cables that contain over one optical fiber, each individually sleeved core is bundled loosely within an all-encompassing outer jacket.

Multimode Fibers – OM1, OM2, OM3, OM4 and OM5

Multimode fibers are identified by the OM (optical mode) designation and their specifications are outlined by the ISO/IEC 11801 standard. Multimode cable disperses the light into multiple paths as it travels down the core. This allows for higher bandwidth over short to medium distances. However, on longer cable runs, multiple paths of light can cause distortion at the receiving end, resulting in an unclear and incomplete data transmission. For this reason, Multimode is generally only used for short distance applications like data centers.

Types of Multimode Fiber Cable and Specifications

OM1

-

Jacket Color – Orange

-

Core Size – 62.5um

-

Data Rate – 1Gb @ 850nm wavelength

-

Distance – Up to 300 meters

-

Application– Short-haul networks, Local Area Networks(LANs) & private networks

OM2

-

Jacket Color – Orange

-

Core Size – 50um

-

Data Rate – 1Gb @ 850nm wavelength

-

Distance – Up to 600 meters

-

Application– Short-haul networks, Local Area Networks(LANs) & private networks

-

Generally used for shorter distances. Has twice the distance capacity has OM1

OM3 – Laser-Optimized Multimode

-

Jacket Color – Aqua

-

Core Size – 50um

-

Data Rate – 10Gb @ 850nm wavelength

-

Distance – Up to 300 meters

-

Uses fewer modes of light, enabling increased speeds

-

Able to run 40GB or 100GB up to 100 meters utilizing an MPO connector

-

Application– Larger Private Networks

OM4 – Laser Optimized Multimode

-

Jacket Color – Aqua

-

Core Size – 50um

-

Data Rate – 10G @ 850nm wavelength

-

Distance – Up to 550 meters

-

Able to run 100GB up to 150 meters utilizing an MPO connector

-

Application– High-Speed Networks, Data Centers, Financial Centers and Corporate Campuses

OM5 – The latest and greatest in Multimode Fiber

-

Jacket Color – Lime Green

-

Fully compatible and can mate with OM3 and OM4 cabling

-

Utilizes a wider range of wavelengths between 850nm and 953nm

-

Designed to support Short Wavelength Division Multiplexing (SWDM)

-

Can Transmit 40 Gb/s and 100 Gb/s

-

Application– High-speed Networks and Data Centers that require greater link distances and higher speeds.

Multimode Fiber Summary

Multimode fiber has come a long way in 30 years. It has evolved with the growing demand for more speed. Since OM1 and OM2 fiber could not support the higher speeds, OM3 and OM4 became the main choice for multimode fiber to support 25G, 40G and 100G Ethernet. With even greater demands on the horizon, OM5 was developed to extend the benefits of multimode fiber in data centers.

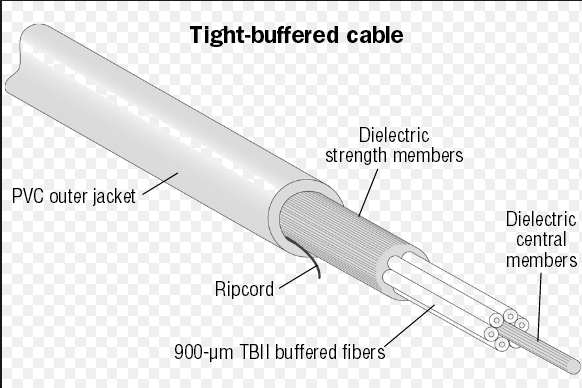

Tight-Buffered Cable, is often called premise or distribution cable. Its design typically offers a smaller package and more flexible cable, and is commonly used for indoor applications, such as in-building, risers, general building and plenum applications, as a result of providing a rugged cable structure to protect individual fibers during handling, cabling and connecting.

BRIEF OVER VIEW OF FIBER OPTIC CABLE ADVANTAGES OVER COPPER:

• SPEED:Fiber optic networks operate at high speeds - up into the gigabits

• BANDWIDTH:large carrying capacity

• DISTANCE:Signals can be transmitted further without needing to be "refreshed" or strengthened.

• RESISTANCE:Greater resistance to electromagnetic noise such as radios, motors or other nearby cables.

• MAINTENANCE:Fiber optic cables costs much less to maintain.

In recent years it has become apparent that fiber-optics are steadily replacing copper wire as an appropriate means of communication signal transmission. They span the long distances between local phone systems as well as providing the backbone for many network systems. Other system users include cable television services, university campuses, office buildings, industrial plants, and electric utility companies.

A fiber-optic system is similar to the copper wire system that fiber-optics is replacing. The difference is that fiber-optics use light pulses to transmit information down fiber lines instead of using electronic pulses to transmit information down copper lines. Looking at the components in a fiber-optic chain will give a better understanding of how the system works in conjunction with wire based systems.

At one end of the system is a transmitter. This is the place of origin for information coming on to fiber-optic lines. The transmitter accepts coded electronic pulse information coming from copper wire. It then processes and translates that information into equivalently coded light pulses. A light-emitting diode (LED) or an injection-laser diode (ILD) can be used for generating the light pulses. Using a lens, the light pulses are funneled into the fiber-optic medium where they travel down the cable. The light (near infrared) is most often 850nm for shorter distances and 1,300nm for longer distances on Multi-mode fiber and 1300nm for single-mode fiber and 1,500nm is used for for longer distances.

Think of a fiber cable in terms of very long cardboard roll (from the inside roll of paper towel) that is coated with a mirror on the inside.

If you shine a flashlight in one end you can see light come out at the far end - even if it's been bent around a corner.

Light pulses move easily down the fiber-optic line because of a principle known as total internal reflection. "This principle of total internal reflection states that when the angle of incidence exceeds a critical value, light cannot get out of the glass; instead, the light bounces back in. When this principle is applied to the construction of the fiber-optic strand, it is possible to transmit information down fiber lines in the form of light pulses. The core must a very clear and pure material for the light or in most cases near infrared light (850nm, 1300nm and 1500nm). The core can be Plastic (used for very short distances) but most are made from glass. Glass optical fibers are almost always made from pure silica, but some other materials, such as fluorozirconate, fluoroaluminate, and chalcogenideglasses, are used for longer-wavelength infrared applications.

Conclusion

Fiber optic cables are sorted in various types from different views. It’s not necessary to remember all of the types, what is more important is to know the features of different fiber optic cables so as to make proper choice when doing purchase. This is what this article is expected to help.