- Related articles

- Optical Transceivers for Cisco WS-C3650-48TQ-S Switch

- All Cisco DWDM-XFP-47.72's information (List price, Specs, Datasheet PDF, Compatibility ma

- What Is GJFJV Fiber Optic Cable?

- Optical Transceivers for Cisco WS-C3650-48PS-S Switch

- Difference between XENPAK and QSFP+

- All Cisco QSFP-40G-PLRL4's information (Specs,Compatibility matrix)

- How to Change PCI-E Speed?

- Difference between GLC-LH-SM and GLC-LH-SMD

- Applicable to 100GBASE-SR4 Standard Optical Transceiver Models

- The Things You Need to Know about 10BASE-SR Ethernet Standards

As the fiber is fragile, the fiber used in various environments must be processed into the fiber with the corresponding mechanical properties in order to prevent the fiber from external damage in the laying, installation, use, maintenance to ensure the smooth network. And now extensive use of outdoor cable, indoor cable in a complex environment cannot give a fundamental guarantee in these performances. Based on this, people developed a design of armored fiber optic cable.

Why use armored fiber optic cable?

In the past, outdoor cables were usually laid in a solid pipe to prevent the cable from the damage by external forces. However, this type of cable laying is very complex and spends a lot of time and labor costs. So it was designed in the cable to add a layer of protective metal armor for the fiber core, that is, the known armored cable. Armored fiber optic cable with anti-pressure and anti-stretch function, can effectively adapt to the harsh outdoor environment with more flexible wiring than the pipeline wiring. Now, armored cable has been widely used in the field of optical communications.

Structure of armored fiber optic cable

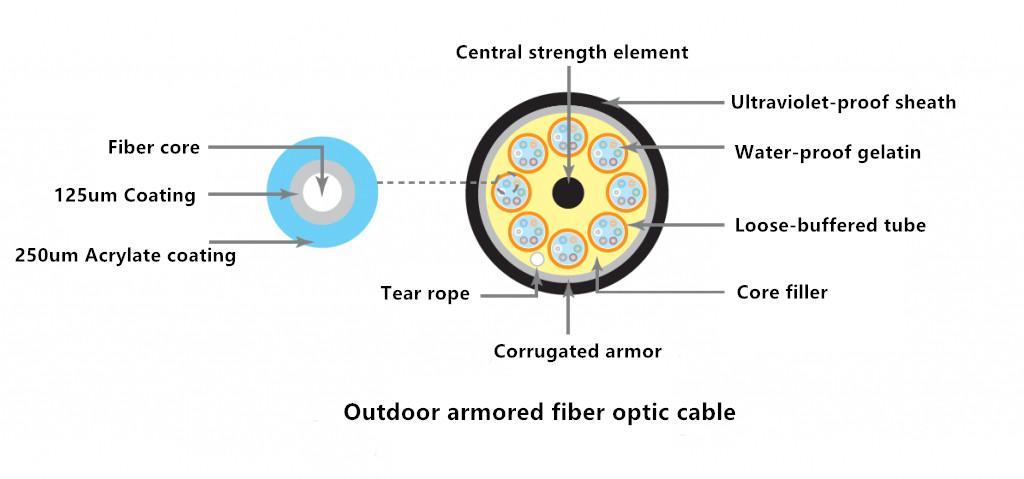

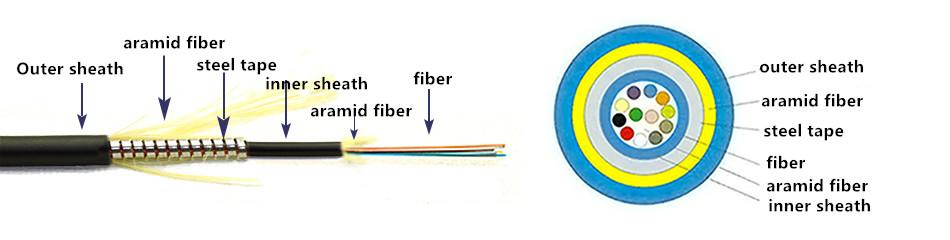

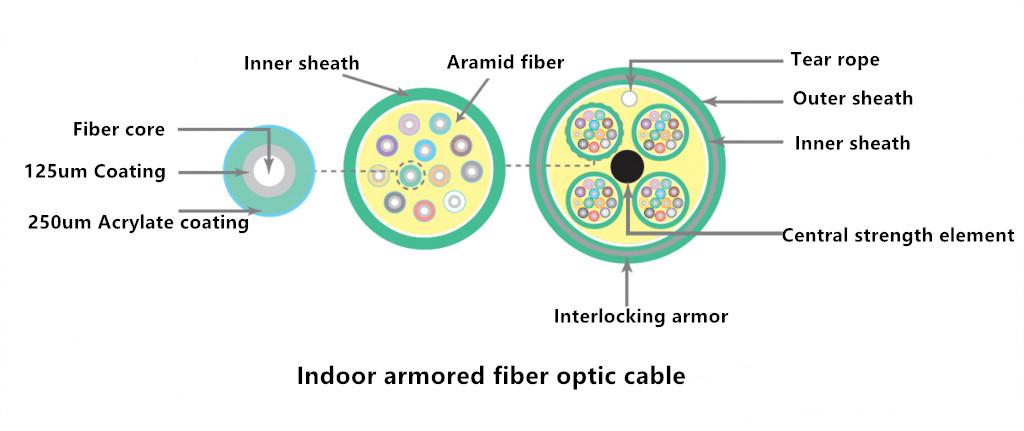

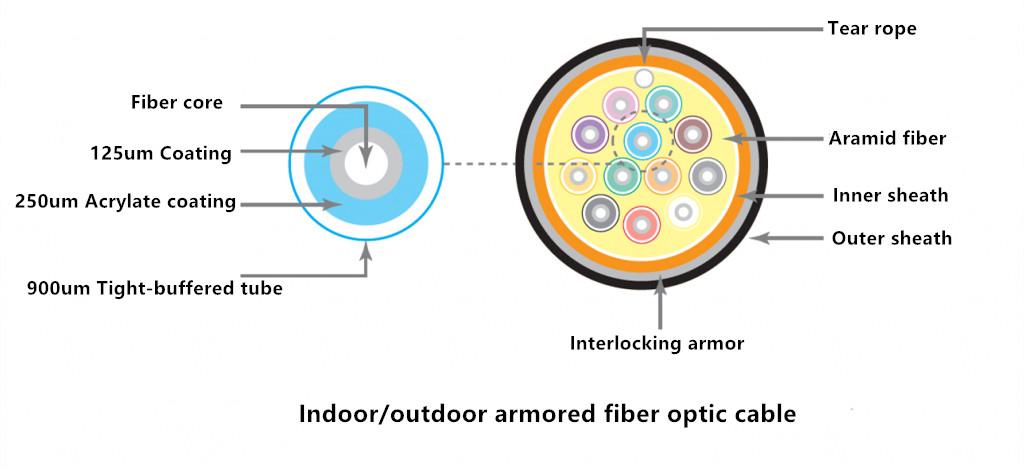

The biggest difference between armored cable and other fiber cables is the design of "metal armor". According to the different structure, fiber types, core numbers, jacket types, the armored fiber optic cable can be divided into multiple types. The following 12-core armored cable is an example to illustrate the specific structure of armored cable. As shown in the picture below, the 12-core armored cable has 12 optical fibers and two inner and outer sheaths. And the metal armor is between the inner sheath and the outer sheath, and a layer of aramid yarn between the outer sheath and the metal armor:

Type of armored fiber optic cable

Armored cable’s "metal armor" usually has two types: interlocking armor and corrugated armor. Interlocking armor is made of aluminum armor cable around the cable, commonly used in indoor and outdoor general environment, with high durability and high-pressure resistance; corrugated armor is wrapped with a steel cable vertical fold, commonly used in the outdoor environment with superior mechanical properties, providing protection against rodent bite.

Application of Armored Cable

According to the different cabling environments, the armored cable can be divided into tight-buffered armored cable and loose-buffered armored cable. Loose-buffered armored cable is usually used in outdoor applications; tight-buffered armored cable can be used in indoor applications and indoor/outdoor applications.

The following picture is the structure drawing of the indoor armored fiber optic cable whose metal armor is interlocking armor, and jacket can be riser or low smoke halogen-free type:

Indoor/outdoor armored fiber optic cable is widely used in the modern telecommunications network, the link of connecting two or more buildings network. The following picture is the internal structure drawing for a common multi-core indoor/outdoor armored cable.

Outdoor armored fiber optic cable uses corrugated armor with high anti-stretch, high-pressure resistance, and high anti-rat bite. The following is its inner structure drawing:

Conclusion

In the field of modern fiber communication, any fiber failure can cause significant financial and material loss, so protecting the fiber is paramount in the installation of fiber communication system. A layer of protective "armor" armored cable wrapped in the fiber meets people's anti-rat bite, moisture-proof, anti-stretch, and other requirements.