- Related articles

- Optical Transceivers for Cisco WS-C3650-48FS-S Switch

- Optical Transceivers for Cisco WS-C3560C-12PC-S Switch

- Used in 10GBASE-USR Standard Optical Transceiver Models

- Optical Transceivers for Cisco WS-C2960-24TT-L Switch

- Optical Transceivers for Cisco IE-2000-8TC-B Switch

- Optical Transceivers for Cisco WS-C3560E-12SD-S Switch

- The difference between DWDM and WDM

- Optical Transceivers for Cisco ME-3600X-24TS-M= Switch

- Optical Transceivers for Cisco SG300-28MP-K9-EU Switch

- Optical Transceivers for Cisco WS-C3560E-48TD-E Switch

On the selection of ADSS fiber optic cable, it is recommended to give preference to the main brands in market, because the manufacturers of the famous brands are more likely to give greater guarantee than others for the sake of their reputation. But in addition to selecting a good supplier, we also need to have a good knowledge of ADSS fiber optic cable and the preventive method for making the best use of them.

Features of ADSS fiber optic cable

light weight, small load;

Large span, up to 1200 meters;

Polyethylene sheath adopted, with a good resistance to electric corrosion;

non-metallic structure, anti-lightning;

Imported aramid, good tensile properties and temperature performance, suitable for northern and other harsh weather;

long life, up to 30 years.

Preventive methods for ADSS fiber optic cable

1 Appearance damage: as some ADSS fiber optic cables are laid through the hills or mountains, bend or abrasion on cables is often seen. If the cable jacket is damaged, which easily causes electric corrosion due to dust and salt environment, this is badly harmful for the life time of cable. Therefore, construction of ADSS fiber optic cable need involve with extra attention, careful check is necessary before laying.

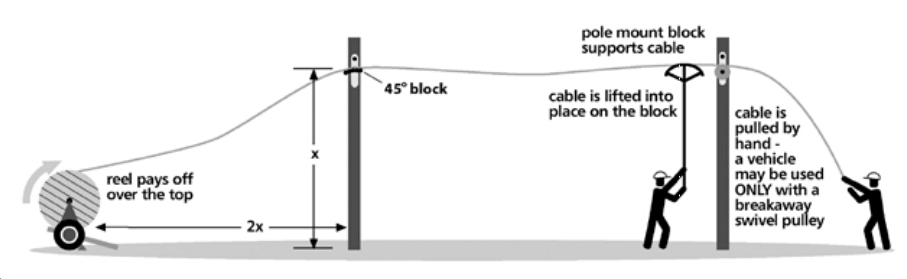

2. Fiber broken and high loss. This phenomenon is mostly caused by the improper force applied in the course of laying cable. Uneven speed, inconstant force applied and looped cable etc., any of these improper operations will hurt fiber, high loss or even fiber broken. There are a large amount of people referring these faults to quality issue of fiber optic cable, but in fact, it’s the improper operation during construction of fiber optic cables that leads to breakdown. Briefly, in order to prevent any accident with fiber optic cables, constant force and uniform speed are quite important in the process of construction.

As the sheathing material and the force components of fiber optic cables are well elastic, there is often no obvious scratch seen on the surface of sheathing after a external force acted on the fiber optic cable for a short time, but actually the optical fiber components inside have already been damaged, this phenomenon normally gives people a bad impression on the quality of fiber optic cable, which is indeed not a true reason for the fault.

Attaching importance to the protection of ADSS fiber optic cable, fiber resources should be uniformly planned and managed by provincial telecommunication organization. Specify the responsibility of operating and managing ADSS fiber optic cable. And any changes or modification on operating lines should be transmitted to relevant departments in time. In addition, strictly implement the regular inspections on each protective and preventive measure.

Conclusion

ADSS fiber optic cable should be maintained and managed in the precondition of clearly knowing the characteristics of used optical cables and the circuit, and it would be better for maintaining ADSS fiber optic cable if having a good knowledge of the common faults and preventive methods.