- Related articles

- Cost Effective Compatible Cisco Transceivers

- Optical Transceivers for Cisco WS-C3650-24PS-S Switch

- Optical Transceivers for Cisco WS-C3750G-12S-S Switch

- What Is External Ethernet Card?

- Cisco 10GbE Optics Modules & Optical Standards

- Difference between single mode and multi mode fiber optic cable

- What are modes in optical fiber?

- All Cisco SFP-OC3-SR's information (List price, Specs, Datasheet PDF, Compatibility matrix

- Optical Transceivers for Cisco SF350-48P-K9-EU Switch

- All Cisco ONS-GC-GE-SX's information (List price, Specs, Datasheet PDF, Compatibility matr

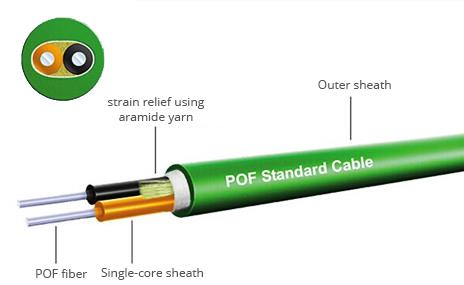

Definition of Plastic Fiber Optic Cable

Plastic Fiber Optic Cable is the types of fiber optic cable that is designed using the polymer. Like glass optical fiber cable, Plastic Fiber Optic Cable is widely used to transmit light through the core of the fiber. Therefore, about 96% of the Plastic Fiber Optic Cable core enhances the transmission of the light. In this case, light includes data or even illumination. Consequently, Plastic Fiber Optic Cable is a critical element in the transmission of light and is governed by the European standards. Its demand is gradually increasing across the world with more users installing this type of cable in their factories as well as their residential homes.

Description Plastic Fiber Optic Cable

Timbercon POF (Plastic Optical Fiber) products are large diameter assemblies constructed of acrylic and fluorinated polymers, for the core and cladding respectively. Similar to traditional glass fiber, POF transmits light/data through the core of the fiber. However, POF assemblies have a core size, in some cases, 100x that of glass fiber. The increased core diameter allows 96% of the core to transmit signal from point-to-point, making it an ideal material for very high bandwidth/signal transmission over very short distances.

Features of Plastic Fiber Optic Cable

Large core size

Low cost

Field service tolerant

Multitude of connector options

Benefits of Plastic Fiber Optic Cable

Very high bandwidth due to large core size

Inexpensive to manufacture resulting in lower product cost

High bandwidth allows product to remain functioning with some scratches and contamination

Connector options allow easy integration with existing systems

Applications of Plastic Fiber Optic Cable

Illumination

Medical

Data communication (specialty)

POF assemblies possess special characteristics that make this product an ideal solution for applications which traditional glass fiber products are not well suited. For applications requiring a very tight bend radius, POF products can generally bend to 25mm with no excessive attenuation. For visible light laser applications, POF assemblies can transmit the signal such that it is visible to the human eye, making the user aware of its attachment to an active laser and allowing them to avoid associated dangers. POF products also have a very wide tolerance for scratching and contamination from the field. This tolerance allows the product to perform at acceptable level despite some compromise in physical condition.

Conclusion

Plastic fiber optic cable has eased the transmission of light from one point to another. Today, the users don’t need to incur a lot of cost in a transmission of data. In fact, plastic fiber optic cable has improved the profit margins of any factories since they don’t incur a lot of cash for transmission purpose. Consequently, plastic fiber optic cable is easy to install as well as to maintain.